The world of manufacturing and product design is in a constant state of evolution, driven by the relentless pursuit of speed, accuracy, and cost-efficiency. For decades, the journey from a digital CAD model to a functional prototype involved a difficult choice: wait weeks for an expensive injection mold or settle for a 3D-printed part that lacks the material properties and finish of the final product.

What is RepMold?

RepMold is an advanced additive manufacturing process specifically engineered for the creation of high-performance, rapid injection molds (molds or tools). Unlike traditional 3D printing which produces the part itself, RepMold uses state-of-the-art printers and specialized composite materials to print the actual mold cavities and cores. These printed molds can then be mounted on standard injection molding machines to produce hundreds, or even thousands, of functional prototypes and end-use parts from engineering-grade thermoplastics.

In essence, RepMold is a bridge—a highly sophisticated and capable bridge—between the agility of 3D printing and the scalability and material integrity of injection molding.

How Does It Work?

The RepMold process seamlessly integrates digital design with traditional manufacturing:

- Design & Preparation: A designer finalizes their part geometry in a CAD program. The mold design (core and cavity) is created around this part, incorporating necessary features like sprues, runners, gates, and cooling channels.

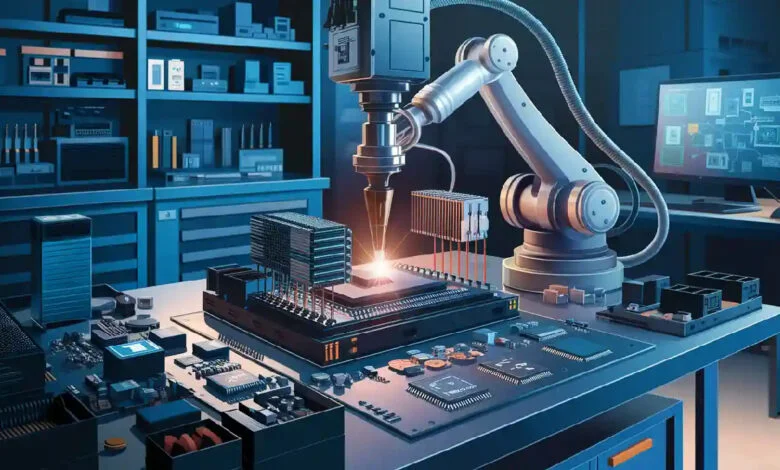

- Printing the Mold: Instead of machining the mold from metal, the mold design is sent to a RepMold system. The printer uses a proprietary process, often based on advanced stereolithography (SLA) or similar technologies, to build the mold layer by layer from a special, high-temperature, high-strength photopolymer resin composite.

- Post-Processing: Once printed, the mold undergoes a post-curing process to achieve its ultimate mechanical properties and thermal stability. It is then lightly finished and assembled onto mold plates.

- Injection Molding: The assembled RepMold tool is installed in a standard injection molding machine. The machine cycles precisely as it would with a metal mold, injecting molten plastic (like ABS, Polypropylene, Nylon, or even filled materials) into the cavity under high pressure and temperature.

- Production & Iteration: The RepMold tool can produce a production run of parts that are identical to what would be made from a final steel or aluminum mold. This allows for rigorous functional testing, market validation, and even small-batch manufacturing. If a design change is needed, a new mold can be printed in a fraction of the time and cost of a metal tool.

Key Advantages of RepMold

- Unmatched Speed: Go from CAD to first injected parts in as little as 24-48 hours, compared to the 4-8 week lead time for machined aluminum molds.

- Radical Cost Reduction: RepMold tools cost a fraction of a machined metal mold, eliminating a massive financial barrier to prototyping and low-volume production.

- Design Freedom & Iteration: The ease and low cost of creating a new mold empower designers to test multiple iterations, explore radical design changes, and optimize parts for manufacturability without financial penalty.

- Real Material Properties: Unlike 3D-printed parts, RepMold-produced parts are made from industry-standard, engineering-grade thermoplastics. This means they have the correct mechanical strength, chemical resistance, and thermal performance for true functional testing.

- Scalability for Bridge Production: RepMold is perfect for low-volume manufacturing (typically 100-1,000+ parts), allowing companies to launch products, fulfill niche market demands, or conduct clinical trials while the permanent hard tooling is being manufactured.

Applications Across Industries

RepMold is a game-changer for:

- Consumer Goods: Rapid prototyping of ergonomic grips, housings, and components.

- Medical Devices: Creating functional prototypes and small batches for clinical trials using biocompatible materials.

- Automotive: Testing under-hood components, connectors, and interior features with the right materials.

- Electronics: Validating the fit, form, and function of enclosures and internal mounts.

The Future is Now

RepMold technology is not meant to replace hard tooling for mass production. Instead, it fills a critical gap in the product development cycle. It democratizes access to high-fidelity prototyping and low-volume manufacturing, allowing innovators and large corporations alike to move faster, smarter, and more creatively than ever before. By blending the digital with the physical, RepMold is truly molding the future of manufacturing.

FAQs

Q1: How many parts can I get from a single RepMold tool?

A: The lifespan of a RepMold tool varies based on the material being injected and the complexity of the part. Typically, you can expect to produce from 50 to 500+ parts from a single mold. For abrasive or high-temperature materials (like glass-filled nylons), the lifespan will be on the lower end, while simpler parts with less abrasive materials can often exceed 1,000 shots.

Q2: What materials can be used in a RepMold tool?

A: RepMold tools are designed to work with a wide range of standard injection molding thermoplastics, including ABS, Polypropylene (PP), Polyethylene (PE), Nylon (PA), Acrylic (PMMA), and TPEs/TPUs. They can also handle many engineering-grade and filled materials, though this will reduce the tool’s lifespan.

Q3: Is the surface finish of a RepMold part different from a part from a metal mold?

A: The surface finish of the final plastic part is a direct replica of the mold’s surface. RepMold tools can achieve very good surface finishes straight off the printer. For glossy or textured parts, the RepMold tool can be polished or chemically treated, or a texture can be applied via a secondary process, though the options are more limited than with metal.

Q4: How does RepMold compare to traditional 3D printing for prototypes?

A: It serves a different purpose. 3D printing is best for form and fit models and very low-strength functional tests. RepMold is for functional validation.

- 3D Printed Part: Made from photopolymer or sintered powder, with anisotropic properties and not the final material.

- RepMold Part: Made from injection-molded thermoplastic, with isotropic properties and identical material performance to the final production part.