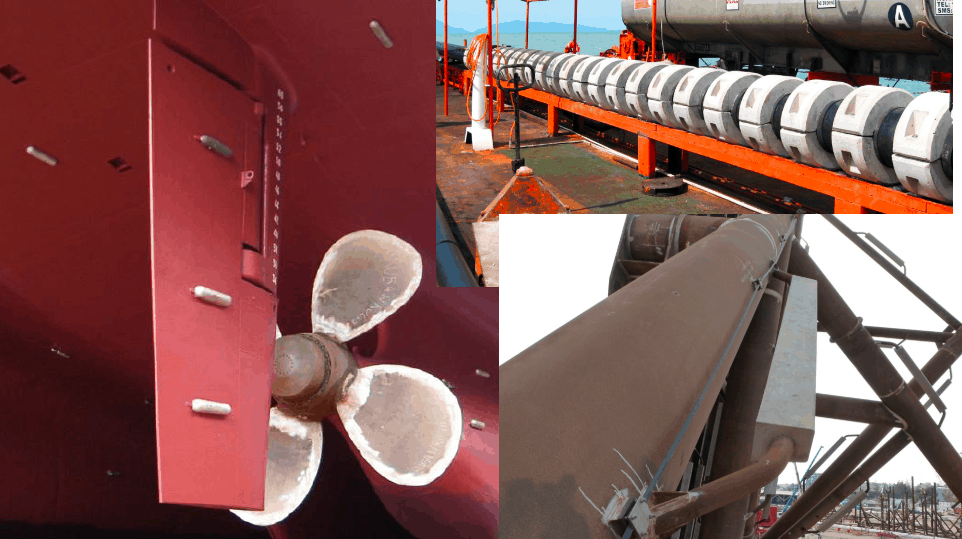

Cathodic letting go is a phenomenon that occurs in electrochemical systems, primarily in structures that utilize cathodic protection (CP) for corrosion control. While cathodic protection is a widely used method to preserve metal structures like pipelines, ships, and storage tanks, cathodic letting go represents a condition where the protective system fails or becomes ineffective, leading to potential structural deterioration.

In this article, we delve into the concept of cathodic letting go, its causes, implications, and strategies for mitigation.

What is Cathodic Letting Go

Cathodic letting go refers to the loss of effective cathodic protection in a metal structure, causing the surface to become susceptible to corrosion. This can happen when the protective potential is compromised or the system fails to provide adequate current to counteract the corrosive forces.

Mechanism of Cathodic Protection

To understand cathodic letting go, it’s crucial to first grasp how cathodic protection works. The process involves applying an electrical current to a metal structure to make it the cathode of an electrochemical cell. This prevents the oxidation (corrosion) of the metal surface by redirecting the electrochemical reactions to a sacrificial anode or an impressed current system.

Causes of Cathodic Letting Go

Several factors can contribute to cathodic letting go, including:

1. Insufficient Current Supply

- A drop in the current supply can reduce the system’s effectiveness, leaving portions of the structure exposed to corrosion.

2. Anode Depletion

- Sacrificial anodes can wear out over time, leading to inadequate protection if not replaced promptly.

3. Coating Damage

- Damaged or deteriorated coatings on the structure can increase the current demand, overwhelming the CP system.

4. Electrical Interference

- Stray currents from nearby electrical systems or structures can interfere with the CP system’s effectiveness.

5. Environmental Changes

- Variations in soil or water resistivity, pH, or temperature can affect the performance of cathodic protection systems.

6. System Design Issues

- Poorly designed CP systems may fail to provide uniform protection across the structure.

Signs of Cathodic Letting Go

Identifying cathodic letting go early is crucial for minimizing damage. Key indicators include:

- Increased Corrosion Rates: Visible signs of rust or pitting on the metal surface.

- Voltage Drops: A decrease in the protective potential below the required threshold.

- Structural Integrity Issues: Weakening or cracking of the protected structure.

- Rapid Anode Consumption: Accelerated depletion of sacrificial anodes.

Implications of Cathodic Letting Go

Failing to address cathodic letting go can have severe consequences, such as:

- Structural Damage: Accelerated corrosion leads to the weakening of the structure.

- Safety Risks: Compromised pipelines or tanks can result in leaks, explosions, or environmental hazards.

- Increased Maintenance Costs: The need for frequent repairs or replacements increases operational expenses.

- Regulatory Non-Compliance: Failure to maintain corrosion protection systems can lead to fines or penalties.

Prevention and Mitigation Strategies

To minimize the risk of cathodic letting go, consider the following measures:

1. Regular Monitoring

- Periodic inspections and potential measurements ensure the CP system is functioning optimally.

2. Anode Maintenance

- Replace sacrificial anodes as needed and ensure impressed current anodes are operating efficiently.

3. Coating Maintenance

- Repair damaged coatings to reduce current demand and enhance protection.

4. Environmental Assessment

- Monitor environmental conditions and adjust the CP system accordingly.

5. Interference Mitigation

- Install mitigation measures like grounding cells to handle stray current interference.

6. System Upgrades

- Modernize outdated CP systems with advanced monitoring and control technologies.

The Role of Technology in Addressing Cathodic Letting Go

Modern cathodic protection systems leverage technology to improve reliability and reduce the risk of cathodic letting go. Innovations include:

- Remote Monitoring Systems: Allow real-time tracking of CP performance.

- Smart Sensors: Detect changes in environmental conditions and system status.

- Automated Controls: Adjust current outputs to maintain optimal protection levels.

Conclusion

Cathodic letting go is a critical issue that can undermine the effectiveness of cathodic protection systems, leading to severe corrosion and structural failures. By understanding its causes, recognizing its signs, and implementing preventive measures, industries can ensure the longevity and safety of their assets.

Regular maintenance, combined with technological advancements, can play a pivotal role in mitigating this challenge and ensuring the integrity of critical infrastructure.