Key Takeaways

- Understanding the vital role of thermal management in ensuring the longevity and performance of electronic devices.

- An overview of various thermal management solutions tailored to different applications and industries.

- Insight into the latest trends and environmentally responsible practices within thermal management.

Why Thermal Management Matters in Electronics

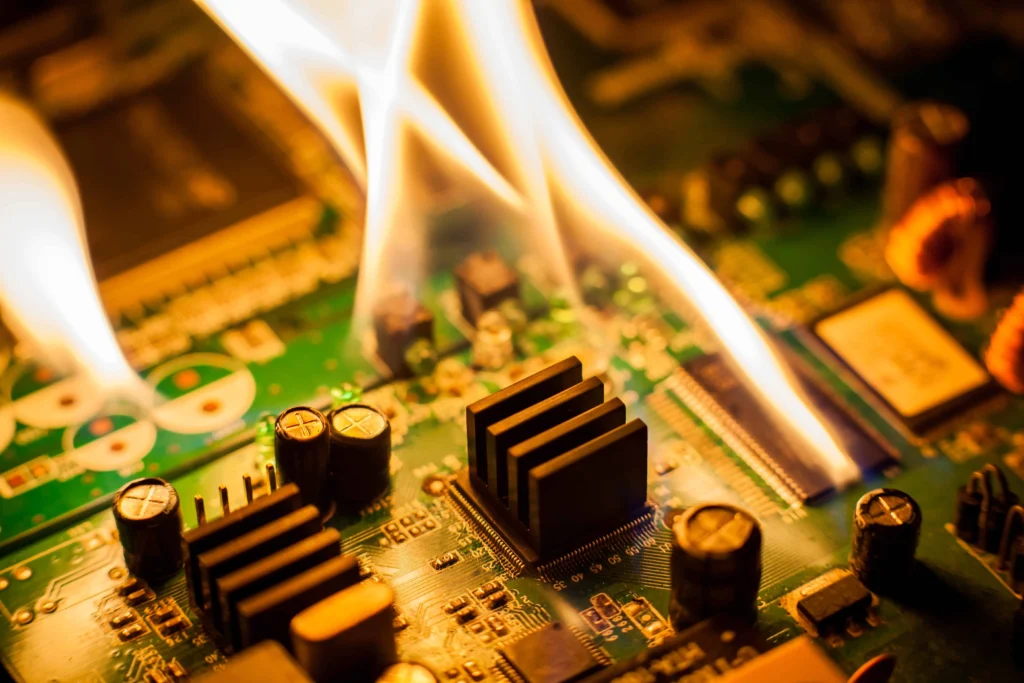

Managing the heat generated by electronic devices is more than a technical challenge—it’s an operational necessity. Electronic components, from processors to power units, give off heat during everyday use, which can build up and degrade performance or damage the components over time. Effective thermal management is vital for preventing these issues, especially as the power density of electronic devices continues to rise, leading to higher temperatures within confined spaces. This directly impacts the reliability, efficiency, and lifespan of these gadgets, making the field of thermal management an essential component of electronics design.

Types of Thermal Management Solutions

Thermal management employs a variety of methods to dissipate heat. Passive cooling solutions such as heat sinks and thermal pads leverage materials with high thermal conductivity to draw heat away from sensitive components. Active solutions, including fans and blowers, force cooler air over or through electronic systems to maintain a controlled temperature. More demanding applications may use liquid cooling systems, which circulate coolants to draw out heat, or thermoelectric coolers, which convert electrical power directly into temperature differentials.

Criteria for Choosing the Right Thermal Management Approach

Selecting the appropriate thermal management solution involves a considered approach. One must first determine the thermal budget, feeling the heat produced during peak operation conditions. Spatial and weight constraints and the acoustic impact of cooling solutions are also critical factors. Economic considerations such as initial costs, maintenance expenses, and energy consumption over the device’s operational lifetime are paramount in decision-making. These factors must be harmoniously balanced to ensure an optimal and sustainable thermal management approach.

Emerging Trends in Thermal Management Technologies

As the electronics industry advances, so do the technologies for managing heat. Innovations in materials science offer new possibilities for thermal interfaces and dissipation, such as graphene and advanced ceramics. Integrating thermal management with IoT devices permits real-time monitoring and prescriptive temperature control through AI algorithms—leading to ‘smart cooling’ solutions. Environmental considerations have led to the developing of more sustainable practices, such as using phase-change materials and low-GWP (Global Warming Potential) refrigerants.

Evaluating the Environmental Impact of Thermal Management

The design and operation of thermal management systems can substantially influence the environmental footprint of electronic devices. Notably, air conditioners and liquid coolers can consume significant amounts of energy. Therefore, enhancing the energy efficiency of thermal solutions is imperative in reducing the overall carbon footprint. Innovations like closed-loop liquid cooling systems demonstrate how technology can reconcile high performance with eco-friendliness.

Maintaining Optimal Device Performance with Regular Thermal Management

Like any mechanized system, electronic devices benefit from regular maintenance to ensure lasting performance. Components such as fans can accumulate dust and debris, impacting their cooling efficiency. Similarly, the thermal interface materials might degrade over time, diminishing their heat transfer capabilities. Proactive maintenance, including cleaning and replacing these components, ensures they continue functioning at their best, mitigating the risk of thermal-related failures.

Understanding the Role of Thermal Interfaces in Heat Dissipation

At the microscopic level, the surfaces of even the most finely polished components are rough, presenting gaps that inhibit efficient heat transfer. Thermal Interface Materials (TIMs) fill these gaps, facilitating improved heat conduction from the element to the heat sink. A properly chosen and applied TIM significantly increases the efficiency of the thermal management system, mainly when working with components that generate substantial heat.

Thermal Management in Extreme Environments

In environments where regular cooling techniques are not viable, such as in space or under the sea, specialized thermal management strategies are essential. Devices in these settings might be subject to intense solar radiation, complete vacuum, or high-pressure conditions that standard solutions cannot address. Here, engineering ingenuity comes to the fore, with systems designed to operate efficiently under such conditions, ensuring device safety and reliability.

Industry-Specific Thermal Management Considerations

Different sectors face distinct thermal challenges. For instance, the high-performance computing industry battles heat as processing powers grow and is often at the forefront of innovative cooling techniques. The automotive industry, especially with the growth of electric vehicles, must manage battery and motor temperatures. Aerospace components may need to withstand dramatic temperature fluctuations. Each sector brings its specific temperature control requirements, which dictate the design and implementation of its thermal management systems.

The Future of Thermal Management: Innovations to Watch

The thermal management landscape is one of rapid innovation and excitement. Developments such as chip-level liquid cooling and solid-state cooling present intriguing possibilities. At the same time, applying machine learning for predictive temperature control can lead to more intelligent, more autonomous systems. As electronic devices evolve, the demand for advanced thermal management approaches that can keep up will only grow. These forward-looking innovations stand poised to redefine the ways we manage heat in electronics far into the future.